| Entered was a PDF, original at: http://www.regulations.gov/#!documentDetail;D=FAA-2011-1279-0009 |

|

|

Highest Wind LLC response to FAA docket 2011-1279 regarding

Airborne Wind Energy Systems (AWES).

Dimitri Cherny Founder, CEO Highest Wind LLC

February 3rd, 2012

General comments on all AWES from Highest Wind LLC.

1. All American AWE system developers are years away from

commercialization. We are all currently in the development and test

phase and will likely remain here for the next three or four years

before any of us have systems ready for purchase.

2. Unlike other aircraft, development of AWE systems requires

frequent, and eventually continuous flight testing, day and night in

all weather conditions for weeks and months on end. Longevity,

survivability, and extremely low maintenance requirements are the keys

to the commercial feasibility of AWE systems. Only by keeping AWE

systems in the air for months at a stretch will any developer be able

to determine whether their system is ready for commercialization. We

are all essentially designing flying vehicles that must be as reliable

as wind turbines – more reliable than the best existing passenger

aircraft.

3. Testing of AWE systems must occur at all the altitudes at which

they will eventually be allowed to fly commercially. Testing at lower

altitudes will enable us to confirm flying vehicle designs but not

entire system designs enough to confirm commercial feasibility.

4. Cost-effective testing of these designs will require a minimum of

restrictions on marking and lighting. Early test systems will all be

considerably smaller than final commercially viable systems, meaning

the additional weight, drag and electrical generation requirements

imposed by lighting and marking devices on small test systems will

adversely impact testing and development.

5. Final commercially viable systems will generally be larger, better

able to handle the additional weight, drag and electrical generation

requirements of lighting and marking devices.

6. Many AWE systems in development utilize “cross-wind motion”, flying

nearly perpendicular to the wind at high speeds. Such motion across

the wind induces high levels of drag in the tether, a problem many

developers are struggling to overcome. The addition of flags or lights

on the tether would increase tether drag even further, compounding

this problem to the point that many otherwise successful AWE designs

might become completely infeasible.

7. As a group, we AWE developers believe we can find a number of

private land-owners around the country willing to host our flight

testing. These private lands would each have hundreds of acres of

uninhabited land adequate in size to contain our “flight cylinders”,

in windy and remote areas already located in Class-G airspace and

experiencing virtually zero aircraft traffic below 3,000 AGL.

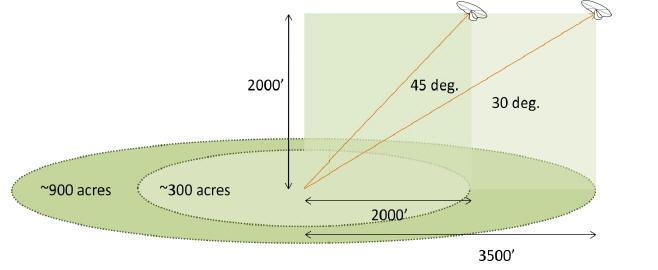

1. Diagram of AWES "Flight Cylinder" and size of footprint depending

on flight angle.

8. If the FAA can designate a specific number of no-fly zones up to

2,000 feet AGL above these private lands, our testing and development

could continue unhindered.

9. In a few years, as AWE developers approach final designs ready for

commercialization and have a better understanding of how the

additional burdens of weight, drag and on-board electrical generation

requirements will impact their systems, further clarification of the

marking and lighting requirements should be made.

10. What we are suggesting is a two-phase approach to the regulation

of AWES. During the testing phase for the next few years, limit us to

specific testing areas we find free of other aviation but reduce our

burden of marking and lighting to an absolute minimum and allow us to

fly in these areas up to 2,000’AGL. After our systems have reached

commercial viability and we have a better understanding or what our

systems can handle, let us all re-visit the issues of marking and

lighting, location and permitting.

Responses to the questions posed by

the FAA regarding AWES.

•General information on a developer’s specific AWES design concept and

plans for operation.

o What type(s) of mechanical devices

are you employing to keep the system aloft?

Highest Wind has arrived at an autogyro design which we believe will

eventually stay aloft in wind speeds as low as eight mph and as high

as eighty mph. Our AWES is of the “ground-gen” type employing a

relatively lightweight flying vehicle (the “glider”) which ascends,

pulling the tether, which spins a generator in the “Energy Trailer” on

the ground. At the end of each ascent, the glider quickly descends

while the tether is reeled in. At some minimum altitude the descent

stops and the ascent cycle starts over again. Ascent/descent cycles

will complete every minute or less, possibly ranging from 500’AGL up

to 2,000’AGL depending on which altitudes have wind speeds of more

than 20mph. On the eventual commercially viable system, each ascent of

the glider will pull the tether with more than a ton of force at a

speed of no less than 20mph producing as much as 100kW of power during

the ascent. Continuous energy output of the system will be some

percent of that maximum – TBD – based on duty cycles, overall system

efficiencies, and wind speeds aloft. We have found a continuous energy

output of 30kWs to be the sweet-spot for our target market of US

farmers.

o What are the physical dimensions

of the device(s) with relation to the above?

Our eventual market-ready system will have a rotor diameter of less

than 50 feet with a small body suspended beneath it no taller than 20

feet. We still have a few years of development and testing before

final dimensions will be available. During those years our testing

will be done on systems no smaller than about a ten foot diameter

weighing about thirty pounds.

o What kind of materials will

comprise this device?

At this point we are unsure if our system will use rotor blades made

of aluminum or some sort of composite material. The internal

structures of the body will be primarily composed of aluminum with

some sort of plastic aero-shell around the body. For the next couple

of years of testing our rotors will continue to be made of wood.

o What are the operational

dimensions (requirement for airspace) for the system?

Our system will fly no lower than about a 30 degree angle above the

horizon. At an elevation of 2,000 feet (our maximum preferred

altitude), depending on wind direction, our flying vehicle could be

anywhere (downwind) within a virtual flight cylinder (see diagram

above) with a radius of 3500 feet (contained within a square space of

1,125 acres). At an elevation of only 1,200 feet (our minimum

preferred), the flight cylinder reduces in size to be contained within

a 405 acre square. We anticipate that further testing will determine

that our angle above the horizon will be considerably higher than 30

degrees, further reducing the ground-space requirement.

o Is there a requirement to

operation more than one device in the air?

Each of our systems will operate independently and will most likely

eventually be purchased in quantities of one by our target buyers in

the US - farmers.

o What are your long-term plans for

this system?

We intend to bring this system to commercialization and sell it in the

US, primarily to farmers in rural areas within Class G airspace.

•Marking and lighting.

o Can you comply with marking and

lighting requirements?

If the marking and lighting requirements to be complied with are those

described in FAA Advisory Circular 70/7460 – 1K, Chapter 11 “Moored

Balloons and Kites”, the answer is “no”. Those marking

requirements are overly burdensome and the lighting requirements would

make our system commercially and technically infeasible. See details

below.

o Can you identify any impacts to

your system when complying with current guidance for marking and

lighting standards?

The current requirement for anti-collision lighting the same as for

towers (L-864 and L-865) will require the development of new lights

meeting those standards which have half the weight, size and energy

requirements of those available today. However, that seems like it

could be possible within the next few years.

The requirement for the same lights on the tether at 350 foot

intervals would make our system commercially infeasible given the

current or future technologies for those lights. We have no easy way

to provide power to those lights along the tether and would face

extreme difficulties with any system to attach or detach those lights

as the tether is reeled in and out. Similarly, the current requirement

for flags every fifty feet on the tether would be very difficult to

achieve.

o What are your plans or how is your

system designed to make the system conspicuous to the flying public?

We are planning to sell our system for use only where there is no

flying public. My pilot training stressed remaining above 3,000 AGL at

all times other than for landings and take-offs. Having toured

agricultural areas in more than forty states, I know virtually zero

aircraft other than the occasional crop duster fly below 2,000 AGL in

class-G airspace more than five miles from any airport. That said, we

plan to provide adequate anti-collision light on the flying vehicle to

make it conspicuous to pilots in all weather conditions.

•Safety to other airspace users and

persons and property on the ground.

o What safety mechanisms or devices

have you designed into the system to ensure all aspects of aviation

safety?

At this point, only anti-collision lights and an on-board alarm

(described below) have been considered for aviation safety. Should the

worst-case situation of a tether-break occur, as with any tethered

flying vehicle, our vehicle will be unstable in un-tethered flight,

settling quickly to the ground.

o What safety mechanisms or devices

have you designed into the system to minimize or mitigate hazards to

persons or property on the ground?

We intend to sell our system only to farmers and other single large

land-holders with primarily uninhabited agricultural land large enough

to contain the entire flight cylinder footprint. That said, in a

worst-case situation of a flying vehicle crash, an on-board alarm will

sound whenever the vehicle descends below some pre-designated

altitude. However, long before an imminent crash, the system is

designed to reel the flying vehicle in at a speed adequate to keep it

aloft and under control to pull it to a safe landing upon its landing

platform.

•Minimized impacts to NAS

facilities.

o What are your plans or how is your

system designed to reduce a large radar cross-section and become less

conspicuous to surveillance systems?

Our eventual flying vehicle ready for commercialization will utilize a

rotor no larger than that of a BlackHawk helicopter with a body below

the rotor less than one quarter the size of the BlackHawk.

o What are your plans or how is your

system designed to reduce impacts to any communication or navigation

systems supporting the NAS?

We anticipate no impacts to communication or navigation systems from a

vehicle no larger than a BlackHawk helicopter.

|